B.C. & F. Tool Company has more small hole gundrilling experience than anyone. The reason is simple. No one else can gundrill holes in the range of .032 to .043 inches in diameter. We can achieve some of the highest diameter to depth ratios possible.

A few of the types of parts we drill successfully include, cannulated titanium and stainless steel bone screws and cannulated drills, taps, drill sleeves, guide shafts and other tools for the surgical/medical instrument industry. Blanks, shafts and tubes for automotive and aircraft suppliers. Materials drilled include difficult to machine 304, 316, and 440 stainless steels. Customers who have used tubing to process their parts have found improved quality, more flexible in design and cost savings to have B.C. & F. Tool gundrill their parts from solid.

Bolt hole circles, intricate patterns, and hole matrices can be drilled with our three axis capability. So, if you need thousands of holes in one part rather than thousands of parts with one hole, we can provide that for you as well.

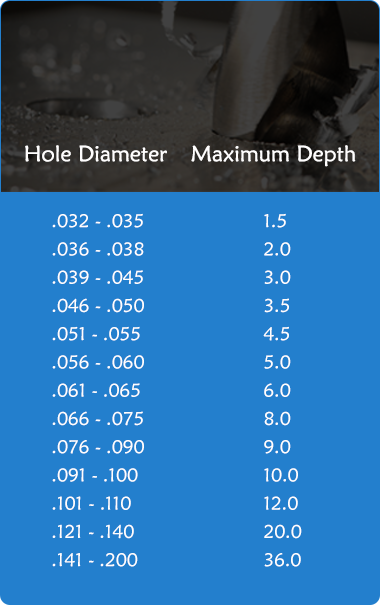

Please review the chart below. If there is a need you have that is beyond the range of the chart, please contact us. We welcome an opportunity to help you find the best solution.